Besides some of the features listed above the real reason for doing this was to cure the fueling problems you get with a tuned engine.

Firstly to produce good top end power and torque this engine needs a cam with a long duration and so a lot of cam over lap.

One problem with a long duration cam is that the inlet valve is held open longer, so when the piston is on its way back up and your inlet valve is still open you get a unwanted pulse going up the inlet port and over the main jet pulling up more fuel, this extra fuel then gets added to the total fuel being used and you end up with a very rich mixture at low to mid engine speeds.

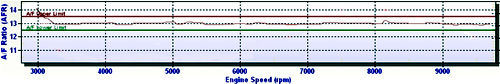

Depending on your setup this can be a big problem, If you look at the graph below of a typical tuned Raptor you'll see the many problems your trying to deal with.

You can see at 3000 to 7000 its seriously rich then at 7500 (peak torque) its on the lean side losing power and possibly causing detonation, after that 8500 and its about right for a short time before heading south again and spoiling the last 1000 rpm.

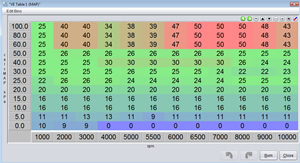

Now looking at the injected engine, No problems anywhere, low down richness gone and perfect fueling all the way to the red line, the engines faster and safer. Quick look at the fuel table and you can see its adjustable for any rpm and throttle position and you can even edit the rpm and tps bins.

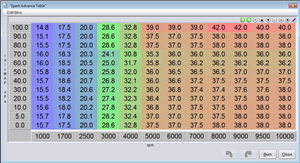

The ignition table is exactly the same with total adjustability, handy if you've gone too high on the compression, just knock a bit of advance off at peak torque (although you'd be better off sorting the compression)

This system can also run in closed loop mode, meaning it monitors the exhaust oxygen content and adjust automatically as required, so if something changed and you started running lean or your air filter got soaking wet and started running too rich it will adjust the fueling to what ever AF target you have set.

![]()

![]()